Aluminium has become one of the most important materials in modern medtech. Whether it’s hospital equipment, diagnostic systems or advanced medical robotics, manufacturers rely on aluminium extrusions and precision-machined profiles because they deliver exactly what healthcare engineering demands: low weight, high strength, excellent hygiene, tight tolerances and long-term durability.

From structural frames to sliding mechanisms, sensor housings and articulated components, aluminium quietly underpins a huge portion of today’s medical devices. And when those components are produced as custom aluminium profiles, the performance gains are even greater; lighter assemblies, cleaner designs, reduced part counts, and far more efficient manufacturing.

Aluminium is everywhere in hospitals and clinical equipment

Walk through any hospital. Aluminium is hidden in plain sight, chosen because it’s strong, lightweight, easy to clean, and ideal for high-use environments.

Where aluminium is used in medical and clinical equipment:

• Hospital beds and stretchers: Profiled aluminium frames, telescopic rails, articulated lifting arms.

• Imaging equipment housings: CT, X-ray and MRI structures where rigidity and reduced weight matter.

• Operating theatre trolleys and surgical carts: Aluminium withstands aggressive disinfectants and constant movement.

• Rehabilitation devices: Mobility aids, physiotherapy frames and lifting supports rely on high strength without excess mass.

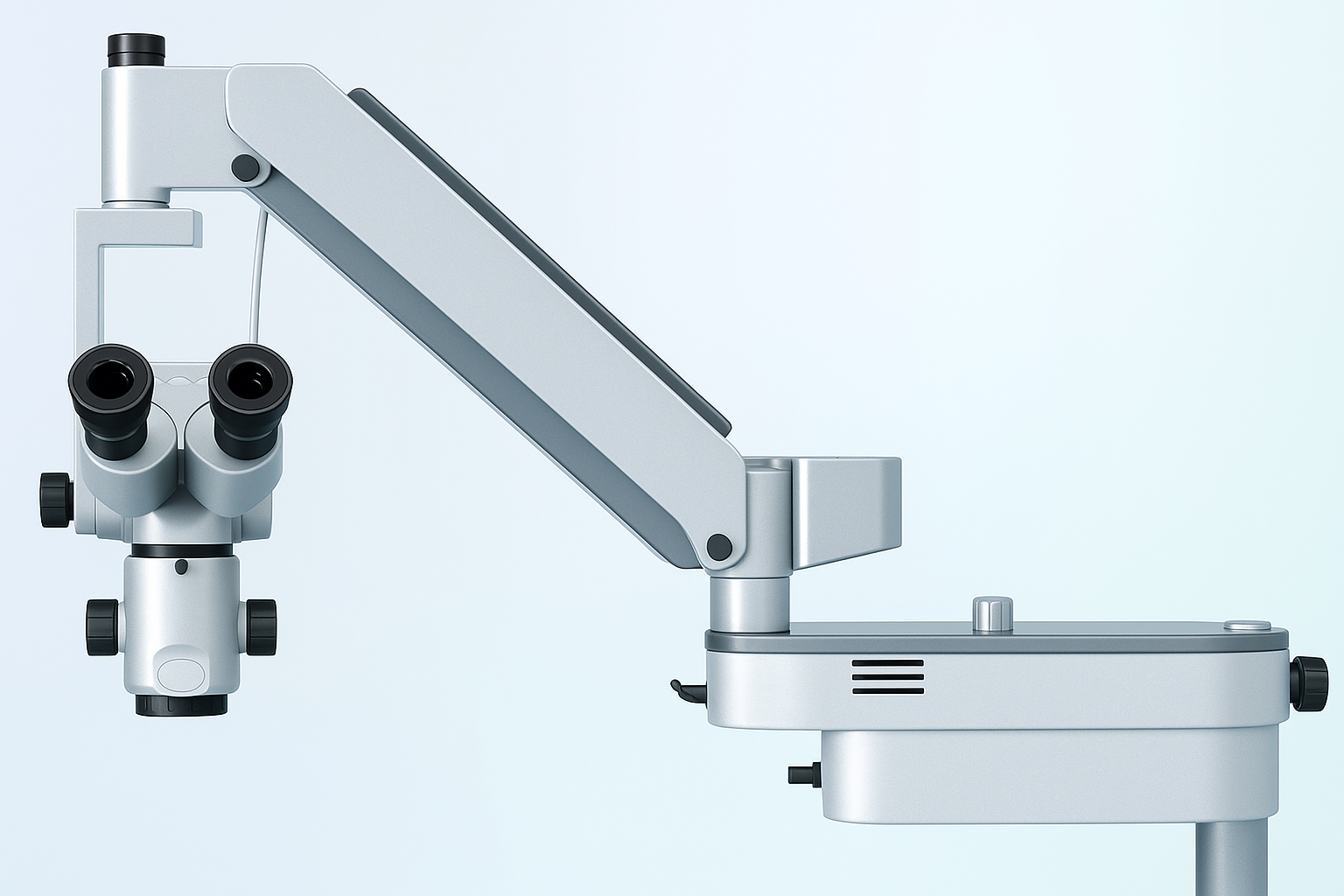

• Laboratory equipment and diagnostic devices: Pump housings, guide rails, internal structural frameworks.

Manufacturers choose precision-machined aluminium profiles because geometry directly affects stability, usability, hygiene, and the device’s long-term durability.

Aluminium solves the hygiene problem that plastics and steel don’t

Hospitals need materials that survive constant cleaning and harsh disinfectants. Aluminium outperforms alternatives here.

Why aluminium is ideal for hygienic medical devices:

• Corrosion-resistant in chemical-heavy environments

• Non-porous and easy to sterilise

• Tolerates daily disinfectant cycles

• Hard-anodising available for extreme wear resistance

• Greater design freedom for complex profiles

Hard-anodised aluminium components survive years of cleaning without peeling, rusting, or degrading. Painted steel and cheaper plastics don’t last long in comparison.

Aluminium improves medical robotics safety, precision, and responsiveness

The growth of medical robotics has made material choice even more critical. Robots need low inertia, high stiffness, smooth motion, and the ability to handle tight tolerances.

Where aluminium is used in medical robotics:

• Robotic arm segments & linkages: Lightweight aluminium reduces overshoot and improves motion precision.

• Motor housings / actuator brackets: Excellent machinability and heat dissipation.

• Robotic bases and structural frames: Custom aluminium extrusions integrate cable channels, sensor mounts, and fixings.

• End-effectors and tool modules: Strong enough for surgical or handling tasks without adding unnecessary mass.

Aluminium keeps robotic systems safe around humans because lighter components means lower inertia. It also enables faster prototyping, which is a major advantage for medtech startups.

The next wave of medtech will rely even more on aluminium

As medtech shifts towards modular systems, mobile devices, and lightweight robotics, aluminium will become more critical.

High-growth opportunities for aluminium in healthcare:

• Modular operating room systems: Click-fit frames built from custom extrusions.

• Portable diagnostic devices: Aluminium minimises clinician fatigue and enhances product durability.

• Reconfigurable hospital furniture: Extrusions allow quick swapping of components.

• Exoskeletons and advanced rehab robotics: High strength-to-weight ratio is non-negotiable.

• Compact lab automation systems: Profiles with integrated wiring, pneumatics and sensor channels.

Design the geometry once, extrude it consistently forever. That reliability matters in regulated medical manufacturing.

Why OEMs use bespoke aluminium profiles

Standard box sections rarely survive long in serious medtech engineering. Most manufacturers eventually move to custom aluminium extrusions because they’re simply more efficient.

How bespoke aluminium profiles improve medical device design:

• Reduce part count by integrating features (mounting bosses, slots, tracks).

• Remove welded brackets, improving structural integrity.

• Improve tolerance control in dynamic systems like robots and imaging equipment.

• Reduce overall weight while maintaining stiffness.

• Simplify cleaning by eliminating crevices and joints.

• Deliver a clean, modern aesthetic for patient-facing devices.

• Cut machining time and overall cost.

In short: a well-designed aluminium profile performs better, looks better, and costs less over the product lifecycle.

Aluminium, the unmatched material in medtech engineering

Aluminium is the material enabling safer surgical robots, cleaner clinical equipment, lighter hospital devices, and more advanced diagnostic systems. And when the geometry is custom-designed, the advantages multiply: lighter assemblies, fewer components, greater hygiene, lower cost, and better performance.

If you’re designing medical robotics, hospital equipment, or clinical devices, aluminium is the most efficient path to better performance, faster manufacturing, and smarter engineering.

Contact us to find out how we can manufacture your aluminium profile so you can bring your medical innovation to life.