Our Story

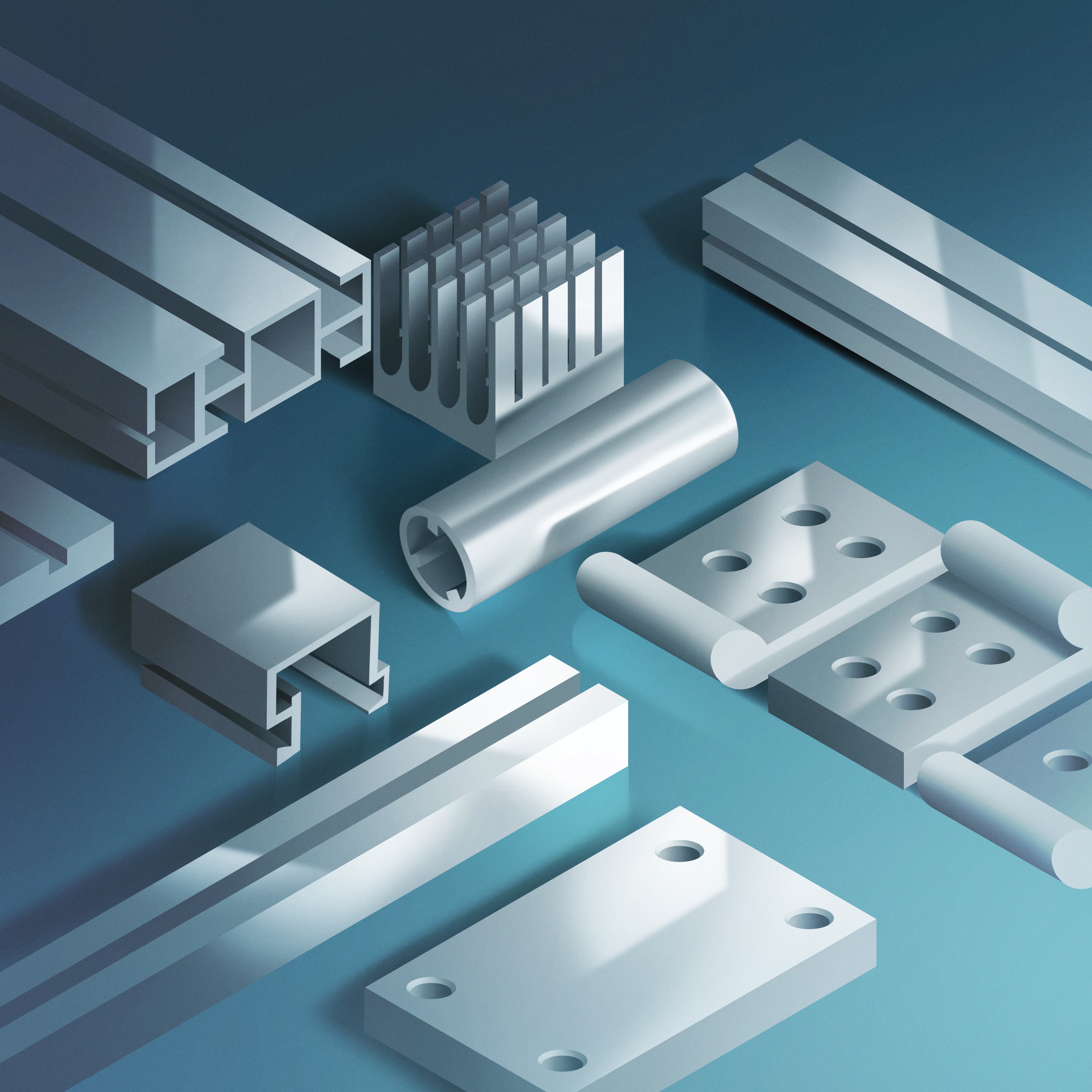

ALUCAD was founded in 2000 to streamline the manufacture of bespoke extruded aluminium products.

We saw the challenges many clients faced like fragmented supply chains from extrusion to machining to assembly, unclear communication, and unnecessary complexity. So we set out to build a better way.

Our vision was to provide high-quality, expertly machined bespoke aluminium products, delivered conveniently, at a price that makes sense. That’s exactly what we do today.

With headquarters in Argentan, France, and a production hub in Foshan, China, ALUCAD delivers an integrated, end-to-end service for custom aluminium solutions. From design and optimised machining to value-added services such as preassembled parts, accessories, and custom packaging, we ensure your aluminium products arrive ready to use, built to strict European standards, without the European costs.

Optimisation at Every Step

We will find the most efficient and sustainable method to produce your bespoke aluminium product. We want to ensure the process we use today remains the smartest and most effective solution for years to come.

Convenience at the Core

Our mission is to make manufacturing easier for you. From custom tooling and flexible batch sizes to pre-assembled parts, we streamline every step. Working with ALUCAD saves you time, money, and reduces friction.

A Partner You Can Trust

We’re a dependable partner. Backed by years of industry experience and a team that listens, responds quickly, communicates clearly, and follows through consistently.

Quality Without Compromise

Every bespoke extruded aluminium product we manufacture meets the highest standards. From material to finish, our work reflects the expertise, consistency, and commitment that define ALUCAD.

Our Production Hub

Our factory in Foshan is the engine behind everything we do.

In 2005, our CEO and founder relocated to China to build this facility from the ground up and remained on the factory floor until 2020, ensuring every process reflected ALUCAD’s standards and values.

Once your bespoke aluminium products are extruded, all machining, assembly, and packaging take place in-house, guided by strict quality control and carried out by a dedicated team that understands your needs and takes pride in every product produced. Each container is then shipped to our French headquarters, where a final quality check is performed before delivery to you. And of course, we undergo annual audits to verify compliance with national regulations, and thanks to our flexibility, one of our clients also carries out independent audits to ensure our processes meet their requirements.

Today, our Foshan team brings an average of over 10 years of tenure per employee, with the manager having been with us for 17, delivering the consistency, skill, and care our clients have come to rely on. Combined with bi-weekly shipments and close coordination with our team in France, our hub delivers the precision and care that set ALUCAD apart.

The team in Foshan

Factory Director

Quality Assessors

Head of Material and CNC, Head of Tapping and Drilling, Head of Packaging