When you’re designing with aluminium, you’re defining how metal will flow, how it will cool, how it will machine, how it will finish, and how it will perform inside your final product.

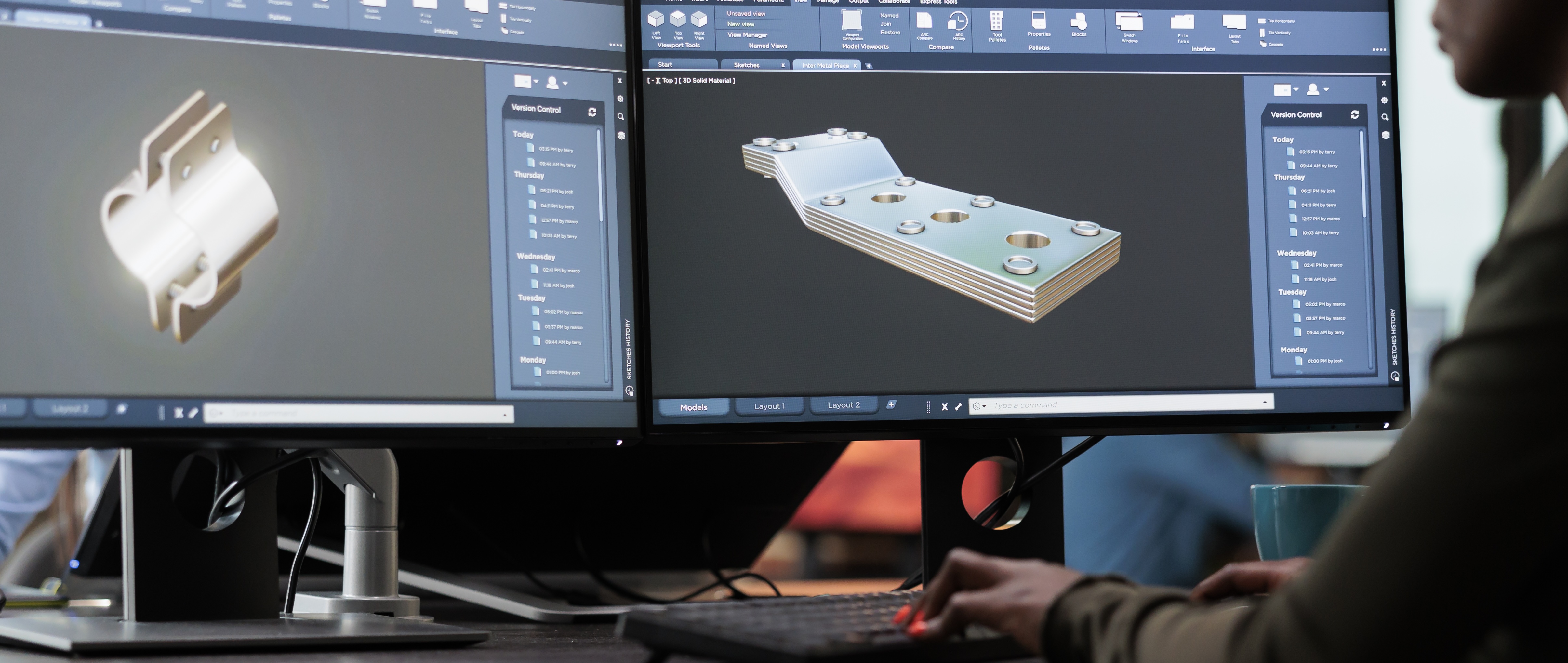

Strong aluminium profile design connects engineering intent with manufacturing reality. A profile which looks perfect in CAD can still become expensive, dimensionally unstable, or cosmetically inconsistent if extrusion behaviour, machining strategy, alloy selection and finishing constraints weren’t considered from the beginning.

Below are the key considerations that matter most when designing your bespoke aluminium profile.

Alloy selection: the foundation of your aluminium profile performance

Designing with aluminium starts with alloy choice. Alloy determines:

• Yield strength and tensile strength

• Elongation at break (ductility vs brittleness)

• Extrudability (how easily complex shapes can be formed)

• Surface finish quality, especially for anodising

• Machinability and tool wear

• Corrosion resistance

For extrusion-based aluminium profile design, engineers typically work with 6060, 6063, 6061 and 6005A.

• 6063 is widely used where surface finish and anodising quality are critical.

• 6060 extrudes very easily and delivers excellent cosmetic consistency.

• 6061 provides higher strength and good machinability but is slightly less forgiving for high cosmetic anodising.

• 6005A offers improved structural performance compared to 6063 while maintaining good extrusion behaviour.

Temper condition (T5, T6, etc.) is equally important. T6 increases strength but reduces ductility compared to T5, which can influence distortion behaviour and post-extrusion machining response.

The wrong alloy can result in:

• Surface variation after anodising

• Cracking in thin or highly stressed areas

• Excessive tool wear during machining

• Difficulty extruding complex hollows

The correct alloy is the one with the best balance among structural load case, cosmetic requirement, corrosion environment, machining intensity, and the full manufacturing sequence from extrusion through finishing.

If you want a deeper technical comparison of mechanical properties across the 6xxx alloy series, you can find detailed breakdowns in our design guide for bespoke aluminium profiles.

Aluminium extrusion: designing for metal flow and dimensional stability

Extrusion is controlled metal flow under pressure. Geometry directly determines how that flow behaves.

The most critical design principle is managing wall thickness. Large variations in thickness cause uneven metal flow and uneven cooling, and uneven cooling introduces residual stress, which leads to twist, bow and dimensional drift over length. It can also contribute to visible shade differences after anodising because thicker and thinner regions respond differently.

Perfect uniformity is not always possible, especially in functional profiles, but thickness transitions should be gradual rather than abrupt. Profiles with extreme asymmetry are more prone to distortion because mass cools at different rates. While complete symmetry is not required, mass distribution should be intentionally balanced wherever possible.

Internal radii are equally important. Sharp internal corners restrict metal flow, increase die stress and reduce die life. Adequate radii improve surface quality, dimensional consistency and long-term die stability.

Extrusion design is not simply about whether the profile can be produced once. It is about whether it can be produced repeatedly, within tolerance, at scale, without excessive die wear or scrap.

Aluminium profile machining: designing for access, stability, and efficiency

Extrusion delivers near-net shape. Machining defines final precision and functional interfaces.

Aluminium profile design must consider how the part will be fixtured. Stable datum faces are essential. Without them, cycle time increases and positional repeatability suffers. If visible cosmetic faces are also used for clamping, surface damage becomes a risk.

Tool accessibility is another critical factor. Deep narrow pockets, thin unsupported ribs and non-standard slot dimensions increase chatter, reduce tool life and slow machining. Designing features to align with standard cutter diameters improves process stability. Where possible, integrate features into the extrusion rather than adding them through machining. Extruded slots, channels and fixing features reduce secondary operations and improve cost efficiency.

Tolerance allocation must be intentional. Tight tolerances increase machining passes, inspection time and reject rates. Precision should be applied only where it directly influences fit, sealing, structural function or assembly alignment.

Aluminium finishing: where design decisions become visible

Finishing processes reveal design weaknesses.

In anodising, differences in wall thickness and mass distribution can cause visible shade variation. This is particularly noticeable in architectural or cosmetic applications. Designing with more consistent section thickness reduces that risk.

Profiles must also allow proper drainage and venting during anodising or powder coating. Closed cavities or deep pockets without exit paths can trap process chemicals or coating media, leading to staining or uneven coating thickness.

Surface transitions influence finish quality. Smooth geometry supports more uniform coating behaviour. Abrupt changes in section can emphasise visual variation.

If the profile is a visible part of your product, finishing behaviour must influence design decisions from the start.

Will it work in production?

Before releasing your aluminium profile design, assess the full lifecycle:

• Will the section extrude without distortion or excessive die stress?

• Is wall thickness balanced to minimise cooling-related movement?

• Is the chosen alloy appropriate for strength, finish and machining?

• Are machining faces accessible and stable for fixturing?

• Are tolerances applied only where function requires them?

• Will anodising or coating highlight section imbalance?

Successful aluminium profile design aligns structural intent with extrusion physics, machining practicality and finishing behaviour.

Want more information?

This article gives you a practical overview of what to consider when designing your aluminium profile.

For a comprehensive breakdown covering alloys, extrusion physics, machining optimisation, finishing strategy, handling and packaging considerations, read our full guide to aluminium profile design.